Sheet metal work is the manufacture of components and products, as well as parts made from metal. Sheet metal work involves a variety of processes including cutting, welding, and bending. It also includes forming, punching, joining and rolling. Sheet metal working produces both soft as well as resistant sheets. Read More…

Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

At Roberts Manufacturing, we specialize in precision sheet metal fabricating that meets the highest standards of quality and craftsmanship. With decades of experience and a deep understanding of metalworking processes, we bring both technical expertise and creative problem-solving to every project.

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

At MET Manufacturing Group, we take pride in delivering comprehensive sheet metal fabrication solutions that combine precision, performance, and innovation. Our team is committed to producing high-quality metal components that meet the demanding standards of industries across manufacturing, construction, and technology.

At L&T Precision, we take pride in being a trusted partner for advanced sheet metal fabrication. We approach every project with a focus on precision, innovation, and consistency, ensuring that the parts and assemblies we produce meet the highest quality standards.

Since 1981, American Industrial has been on the cutting edge of all things sheet metal. This has helped us achieve our spot as a leader of the industry.

More Sheet Metal Work Companies

Sheet Metal Work: Comprehensive Guide to Processes, Applications, and Benefits

Sheet metal work is a cornerstone of modern manufacturing, construction, and industrial fabrication. The versatility, strength, and adaptability of sheet metal make it essential for an array of industries, from automotive and aerospace to architecture and energy production. Whether you are seeking information on sheet metal fabrication, comparing sheet metal work companies, or evaluating materials for your next project, this guide provides in-depth insights into processes, applications, benefits, and decision factors. Explore below to discover everything you need to know about sheet metal work and how to select the right sheet metal service provider for your needs.

Understanding Sheet Metal and Alloy Properties

The properties of sheet metal are determined by the type of alloy used during its production. Alloying elements such as nickel, silicon, chromium, copper, titanium, molybdenum, and niobium are commonly added to liquid steel during the metalworking process. Each element imparts distinct characteristics—such as corrosion resistance, ductility, strength, or electrical conductivity—affecting both the workability and end-use performance of the sheet material.

Sheet metal can be produced from various grades of aluminum, carbon steel, stainless steel, and other metals such as copper, brass, and titanium. Selecting the right alloy and thickness is critical, whether your application requires lightweight materials for aerospace components or high-strength steel for construction.

Curious about which materials are best for your project? What are the differences between aluminum and steel sheet metal? Contact our experts for a detailed comparison and personalized recommendations.

Types of Sheet Metal Work Processes

Sheet metal fabrication encompasses a wide range of processes designed to transform flat metal sheets into functional components, assemblies, and end products. These processes—ranging from forming and cutting to joining and finishing—allow manufacturers to achieve precise specifications and meet the demands of diverse industries. Below, we explore the most common sheet metal work processes in detail:

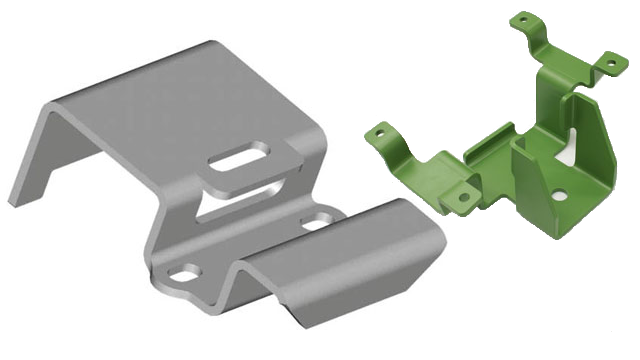

Forming

Sheet metal forming is a manufacturing process where metal sheets undergo plastic deformation to change their shape without compromising material cohesion. Key forming techniques include rolling, bending, stamping, deep drawing, and forging. During hot forming, metal is shaped at elevated temperatures, enabling greater formability and reduced forces compared to cold forming, which is carried out at room temperature for more precise tolerances and improved surface finish.

Industries like automotive and aerospace frequently rely on forming to produce panels, frames, brackets, and complex enclosures. The choice between hot and cold forming depends on the desired mechanical properties, dimensional accuracy, and production volume.

Separation

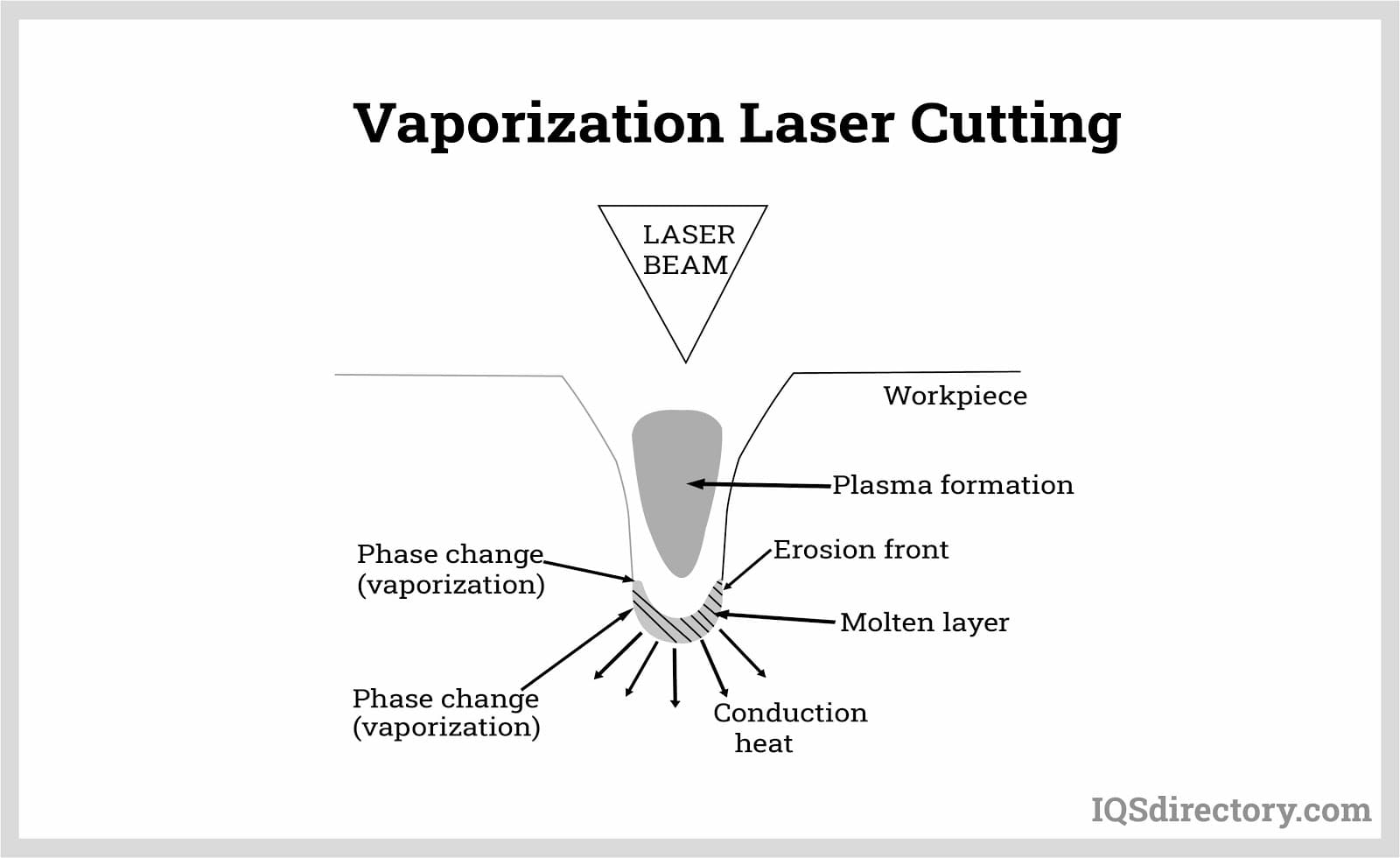

Separation refers to processes that divide or cut the sheet metal, altering its shape by breaking the cohesion in specific regions. Common separation methods include shearing, blanking, laser cutting, waterjet cutting, and punching. These techniques are essential for creating precise profiles, holes, and cutouts in metal sheets with minimal material waste.

Modern fabrication shops often utilize advanced CNC (computer numerical control) machinery for high-speed, high-precision separation tasks, ensuring repeatable quality in large-scale production.

Cutting

Cutting is a core aspect of sheet metal fabrication, involving a variety of processes such as milling, sawing, drilling, filing, thermal cutting (including plasma and oxy-fuel), lapping, broaching, and honing. Each technique is chosen based on the required accuracy, material type, and end-use application.

For instance, laser cutting is ideal for intricate designs and tight tolerances, while plasma cutting offers speed and versatility for thicker materials. Waterjet cutting is preferred when heat-sensitive materials are involved, as it avoids thermal distortion.

Looking for advice on the best sheet metal cutting method? Request a quote or consultation to compare methods for your specific needs.

Joining

Sheet metal joining techniques are used to assemble two or more metal components into a single structure. The most common joining methods include welding (MIG, TIG, spot welding), soldering, riveting, bolting, adhesive bonding, and crimping. The choice of method depends on the required strength, joint configuration, material compatibility, and intended application.

For permanent, high-strength assemblies, welding is often preferred—particularly in automotive frames, construction beams, and heavy machinery. For removable or non-permanent joints, fasteners like screws, bolts, and rivets are commonly used. Advanced joining techniques may also involve hybrid methods, combining mechanical fixation and adhesives for optimal performance.

In addition to basic manual and automated equipment, specialized tools such as impact wrenches, soldering irons, and rivet guns are integral to efficient and precise joining processes.

Surface Treatment

Surface treatment, or surface finishing, involves altering the surface properties of sheet metal components to achieve desired aesthetics, protection, or functional performance. Common surface treatment processes include painting, powder coating, anodizing, galvanizing, electroplating, passivation, and polishing.

Surface treatments enhance corrosion resistance, increase wear resistance, improve electrical conductivity, and provide decorative finishes. In sectors such as electronics, medical devices, and architectural metalwork, precise surface engineering is critical for both appearance and long-term durability.

Applications of Sheet Metal Work

Sheet metal fabrication is fundamental to countless industries, supporting the creation of components, assemblies, and finished products that are integral to modern life. Here are some of the most common applications for sheet metal work:

- Automotive and Transportation: Sheet metal is essential for manufacturing car bodies, chassis, panels, hoods, fenders, engine components, as well as bodies and frames for airplanes, ships, trains, and heavy-duty vehicles.

- Energy and Electrical Industry: Utilized in the production of transformers, enclosures for electrical machinery, switchgear, battery housings, and renewable energy equipment such as wind turbine components and solar panel frames.

- Building and Construction: Critical for architectural metalwork, roofing solutions, rain gutters, ductwork, wall panels, and structural elements in commercial, residential, and industrial buildings.

- Decorative and Artistic Features: Used for producing custom doors, arches, railings, sculptures, and window frames. Precious metals like silver, gold, and platinum are sometimes employed for high-end architectural accents.

- Consumer Products: Common in the manufacture of appliances, furniture, home electronics, lighting fixtures, and kitchenware.

- Medical and Laboratory Equipment: Sheet metal is used to create durable, hygienic housings for diagnostic devices, surgical equipment, hospital furniture, and cleanroom components.

- Industrial Machinery: Fabricated into machine guards, mounting brackets, conveyor systems, industrial enclosures, and custom tooling.

Have a specific application in mind? See how sheet metal work fits your industry or browse our project gallery for real-world examples.

Benefits of Sheet Metal Work

Companies choose sheet metal work because of its many advantages. Whether you are looking for cost-effective manufacturing, high-volume scalability, or custom one-off solutions, the benefits of sheet metal fabrication are significant:

- Durability: Sheet metal components are highly resistant to impact, wear, and environmental conditions, making them ideal for demanding applications.

- Precision: Modern CNC machinery enables tight tolerances and repeatable accuracy, ensuring components fit and function as intended.

- Aesthetics: Advanced finishing processes provide attractive, professional appearances suitable for visible or decorative applications.

- Cost-Effectiveness: Efficient material usage, rapid prototyping, and scalability make sheet metal work cost-competitive at both low and high production volumes.

- Strength-to-Weight Ratio: Many alloys offer high strength while remaining relatively lightweight, making them suitable for transportation, aerospace, and portable equipment.

- Versatility: Compatible with a wide variety of metals, thicknesses, and shapes, sheet metal can be fabricated into everything from intricate enclosures to large structural beams.

- Customization: Sheet metal fabrication supports custom designs, rapid prototyping, and flexible manufacturing to meet unique project requirements.

- Sustainability: Many sheet metals are recyclable, and efficient fabrication processes minimize waste, contributing to environmentally responsible manufacturing.

Looking to maximize the advantages of sheet metal work in your project? Send a quote request or consult with our engineering team to discuss your needs.

Key Considerations When Choosing a Sheet Metal Work Company

Selecting the right sheet metal fabrication company is a crucial step that can make or break your project. With countless providers offering varying expertise, equipment, and service levels, it’s important to evaluate your options carefully. Here’s how to ensure you find a reliable partner for your sheet metal needs:

1. Capabilities and Experience

Assess each company's technical capabilities, including their proficiency in forming, cutting, welding, and finishing. Look for experience with your specific material and application. Do they offer custom metal fabrication, rapid prototyping, or large-scale production?

2. Equipment and Technology

Modern fabrication relies on advanced machinery such as CNC laser cutters, automated press brakes, and robotic welding systems. Verify that your chosen provider uses state-of-the-art equipment to ensure quality, consistency, and efficiency.

3. Quality Assurance and Certifications

Consider companies that hold industry certifications such as ISO 9001 or AS9100, indicating a commitment to quality control and continuous improvement. Ask about their inspection processes, material traceability, and documentation practices.

4. Turnaround Time and Capacity

Can the company meet your project deadlines? Evaluate their lead times, production capacity, and flexibility to accommodate urgent or large-scale orders. Timely delivery is essential for project success.

5. Customer Service and Communication

Clear, responsive communication is vital. Choose a company that listens to your requirements, provides expert guidance, and keeps you informed throughout the fabrication process.

6. Price and Value

Obtain detailed quotes and compare pricing, but also consider the overall value—quality, reliability, and service—rather than just the lowest cost. A trustworthy partner will help you avoid costly mistakes and ensure long-term satisfaction.

Ready to compare sheet metal work companies? Use our sheet metal work manufacturers directory to review business profiles, explore areas of expertise, and request quotes from top-rated providers. Our website previewer helps you quickly see what each company specializes in, while our simple RFQ form lets you contact multiple sheet metal work companies with the same message—making your vendor selection process fast and efficient.

Frequently Asked Questions About Sheet Metal Work

What metals are most commonly used in sheet metal fabrication?

The most popular materials include aluminum sheet metal, stainless steel sheet metal, carbon steel, copper, and brass. Each offers unique properties in terms of strength, corrosion resistance, conductivity, and workability.

How do I choose the right sheet metal thickness for my project?

The ideal thickness depends on application requirements such as strength, weight, flexibility, and cost. Industry standards use gauge numbers or millimeters to specify thickness. Consult with our engineers for guidance specific to your use case.

What are the latest trends in sheet metal fabrication?

Innovations include automation with robotics, additive manufacturing (3D printing of metal), high-precision laser and waterjet cutting, and the integration of CAD/CAM software for rapid prototyping and digital manufacturing.

Can sheet metal work be customized for unique designs?

Absolutely. Modern fabrication shops offer high levels of customization, from one-off prototypes to large-scale production runs. Submit your design files or CAD drawings for a custom quote.

What factors affect the cost of sheet metal fabrication?

Key cost drivers include material type and thickness, complexity of design, quantity, finishing requirements, and turnaround time. Volume discounts may apply for large orders.

Get Started With Your Sheet Metal Project

Whether you are a manufacturer, architect, engineer, or DIY enthusiast, partnering with the right sheet metal fabrication company is vital for project success. Compare top providers using our manufacturers directory, explore their business profiles, and connect directly for more information or a detailed quote. Our team is here to support your project from concept through completion—delivering quality, value, and expert service every step of the way.

Need help choosing the best sheet metal work solution? Contact us for a free consultation or use our online quote request form to get started today.

Broaching

Broaching CNC Machining

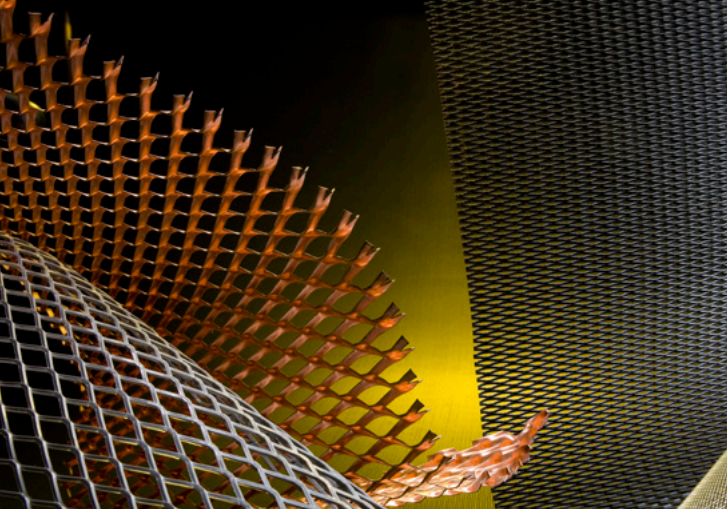

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

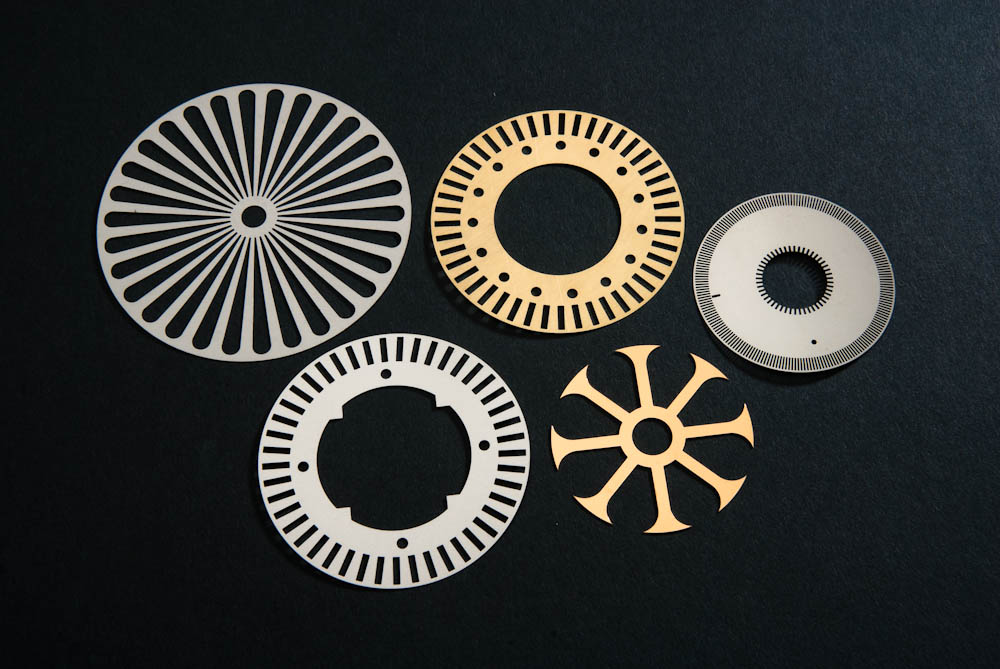

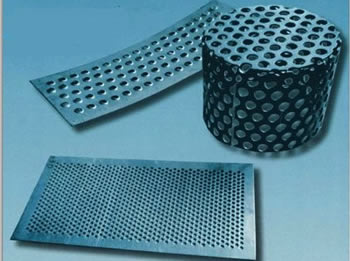

Metal Fabrication Perforated Metals

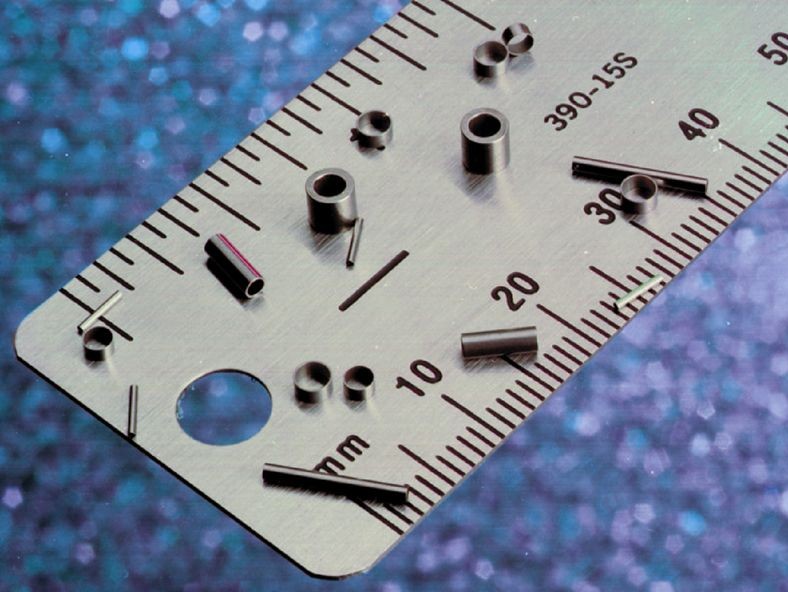

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

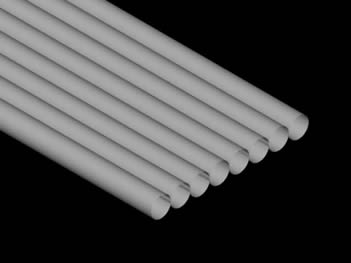

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services