Sheet metal parts are products that are formed from thin flat pieces of metal, mostly by an industrial process. These sheet metal parts are single items that can be formed for use as-is, or they can be joined together in many configurations to create a larger item like a weldment. From there, weldments and additional sheet metal parts can be combined by joining them together to create metal assemblies in a variety of shapes and sizes. Read More…

Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

At Roberts Manufacturing, we specialize in precision sheet metal fabricating that meets the highest standards of quality and craftsmanship. With decades of experience and a deep understanding of metalworking processes, we bring both technical expertise and creative problem-solving to every project.

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

At MET Manufacturing Group, we take pride in delivering comprehensive sheet metal fabrication solutions that combine precision, performance, and innovation. Our team is committed to producing high-quality metal components that meet the demanding standards of industries across manufacturing, construction, and technology.

At L&T Precision, we take pride in being a trusted partner for advanced sheet metal fabrication. We approach every project with a focus on precision, innovation, and consistency, ensuring that the parts and assemblies we produce meet the highest quality standards.

Since 1981, American Industrial has been on the cutting edge of all things sheet metal. This has helped us achieve our spot as a leader of the industry.

More Sheet Metal Part Companies

Weldments

Weldments are fabricated assemblies created by joining multiple sheet metal components through welding techniques. These assemblies can range from simple to highly complex, depending on the project’s size, function, and required strength. Weldments are fundamental in creating robust, custom sheet metal structures for a wide variety of industries—including automotive, aerospace, heavy equipment, and architectural metalwork. When weldments are combined with additional fabricated elements such as panels, brackets, or fasteners, they form complete sheet metal assemblies designed to meet precise engineering specifications.

Types of Sheet Metal Parts

Sheet metal fabrication encompasses a comprehensive range of part types, each tailored to specific requirements, applications, and industries. Understanding the different categories of sheet metal parts is essential for selecting the right solution for your project.

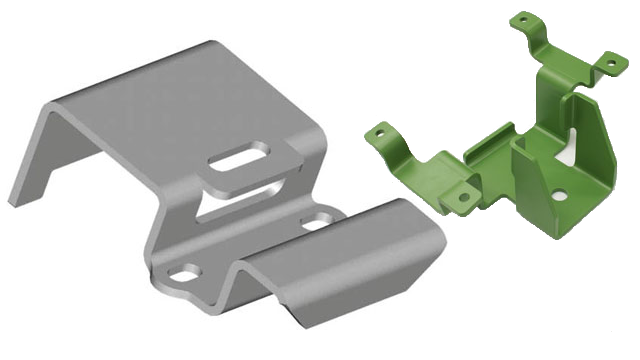

Sheet Metal Brackets

Sheet metal brackets are some of the most versatile and widely used components in metal fabrication. These brackets can be custom designed and manufactured in virtually any size, thickness, or material type, depending on application needs. Small brackets are commonly found in consumer electronics, enclosure shelves, and machinery, while larger brackets provide structural support in building construction and industrial installations. The geometry of sheet metal brackets—such as L-brackets, Z-brackets, and gusset brackets—directly influences their load-bearing capacity, installation method, and suitability for specific environments.

For example, Z-brackets are typically used for mounting offset parallel surfaces inside electrical enclosures or control panels, ensuring stability and precise alignment. Gusset brackets, which often feature a triangular profile, are engineered to reinforce joints and provide extra rigidity in structural frameworks. L-brackets are ideal for connecting vertical and horizontal surfaces—such as installing shelves or mounting devices within enclosures. Custom-formed brackets can also accommodate cable management, ventilation, or specific mounting hardware, demonstrating the flexibility of sheet metal fabrication.

Metal Hinges

Metal hinges are essential hardware components that enable rotational movement between two connected metal parts or surfaces. In sheet metal assemblies, hinges play a vital role in applications requiring repeated opening and closing, such as access doors, cabinets, control panels, and machinery covers. Common types include piano hinges, butt hinges, and concealed hinges—each offering unique benefits in terms of durability, load capacity, and aesthetic integration. High-quality sheet metal hinges are designed for reliability, long service life, and smooth operation even in demanding industrial environments.

Industrial Sheet Metal Supports

Sheet metal supports encompass a broad category of fabricated components used to reinforce structures, distribute loads, and maintain alignment in construction and industrial projects. Typical examples include support poles, beams, struts, pipes, tubes, and mounting brackets. These parts are manufactured from durable materials like galvanized steel, stainless steel, or aluminum for optimal strength, corrosion resistance, and longevity. Industrial sheet metal supports are critical in HVAC systems, piping installations, cable tray assemblies, and building frameworks, ensuring structural integrity and compliance with safety standards.

Commercial Sheet Metal Frames

Sheet metal frames serve as the foundational skeletons for a wide range of products, equipment, and architectural features. From large-scale structural frames used in commercial buildings and industrial machinery to smaller frames for doors, windows, shelving, and electronic enclosures, these assemblies are engineered for precise fit, functionality, and ease of integration. Sheet metal frames can be fabricated from structural steel for heavy-duty requirements or lighter materials like aluminum for weight-sensitive applications. Customization options include powder coating, anodizing, and other surface treatments to enhance aesthetics and environmental protection.

Custom Sheet Metal Components

If your project requires unique geometries, specialized materials, or advanced functionality, consider custom sheet metal components fabricated to your exact specifications. These parts may include enclosures, chassis, guards, covers, brackets, or intricate assemblies designed for OEM equipment, automation systems, medical devices, and more. Custom fabrication leverages technologies such as laser cutting, CNC punching, precision bending, and robotic welding to achieve consistent quality and tight tolerances. Explore how custom sheet metal parts can enhance your next project.

Applications of Sheet Metal Parts

Sheet metal parts are essential in countless industries and product categories, thanks to their strength, versatility, and cost-effectiveness. Here are some of the most common and high-value applications for sheet metal fabrication:

- Automotive Manufacturing: Sheet metal components form the backbone of car and truck bodies, chassis, engine mounts, brackets, and interior/exterior panels. Precision-formed metal parts ensure safety, performance, and durability in vehicles of all types.

- Aerospace Engineering: Lightweight yet strong sheet metal parts are integral to airplane fuselages, wings, air ducts, and structural supports. Advanced materials like titanium, aluminum alloys, and stainless steel enable high performance in demanding flight environments.

- Major Appliances: Household and industrial appliances such as refrigerators, ovens, washing machines, and HVAC units rely on custom sheet metal parts for enclosures, structural frames, and mounting brackets.

- Food & Beverage Packaging: Tinplate and other food-grade sheet metals are still widely used for cans, containers, and packaging solutions, offering hygiene, recyclability, and tamper resistance.

- Building & Architecture: Sheet metal is a preferred material for roofing, cladding, gutter systems, wall panels, and decorative facades in residential, commercial, and industrial construction. Its weather resistance, malleability, and design flexibility allow for innovative architectural solutions.

- Electrical & Power Generation: High magnetic permeability materials, such as laminated steel cores, are essential for transformers, electric motors, and generators, maximizing efficiency and performance in power systems.

- Decorative & Artistic Uses: Beyond industrial functions, sheet metal parts are used in custom signage, sculpture, furniture, and horse tack, where precision fabrication meets aesthetic design.

- Industrial Manufacturing & Automation: Custom sheet metal enclosures, control panels, machine guards, and precision parts are standard in automated production lines, robotics, and process equipment, ensuring safety and operational efficiency.

- Electronics & Telecommunications: Sheet metal shields, chassis, and racks provide electromagnetic interference protection, cooling, and structural support for servers, switches, and sensitive electronic devices.

- Medical Equipment: Medical device enclosures, carts, and brackets made from stainless steel or aluminum meet strict hygiene requirements and offer long service life in healthcare settings.

Benefits of Sheet Metal Parts

Leveraging sheet metal parts in your designs and operations offers a host of advantages over alternative materials and manufacturing methods. Here’s why so many industries rely on precision-fabricated metal components:

Strength and Durability

Sheet metal, especially when fabricated from stainless steel, carbon steel, or aluminum alloys, delivers exceptional mechanical strength and resilience. These materials can withstand high temperatures, heavy loads, and harsh environments, making them ideal for structural, automotive, and aerospace applications. Corrosion-resistant coatings and surface treatments extend product lifespan even further, ensuring performance in both indoor and outdoor settings.

Malleability and Design Flexibility

One of the hallmark benefits of sheet metal fabrication is its malleability. With advanced manufacturing techniques such as laser cutting, CNC bending, and deep drawing, sheet metal can be precisely formed into complex shapes and contours without sacrificing strength or integrity. This enables engineers and designers to innovate freely, developing custom enclosures, brackets, housings, and assemblies that meet exacting requirements. Whether you need tight-tolerance parts or large-scale formed panels, sheet metal delivers unmatched design flexibility.

Replaceability and Modularity

Standardized sizing and modular design principles make sheet metal parts highly replaceable. Instead of replacing entire assemblies, individual components can be swapped out quickly and cost-effectively—streamlining maintenance, minimizing downtime, and reducing lifecycle costs. This approach is particularly valuable in industries where operational continuity and serviceability are top priorities, such as manufacturing, telecommunications, and transportation.

Sustainability and Recyclability

Sheet metal parts support sustainability goals by utilizing recyclable materials such as steel and aluminum. These metals can be repurposed indefinitely with minimal loss in quality, reducing environmental impact and supporting circular economy initiatives. Many manufacturers also offer eco-friendly processes, including water-based coatings and energy-efficient production, further enhancing the green credentials of sheet metal solutions.

Cost-Effectiveness and Efficiency

Compared to plastics, castings, or machined parts, sheet metal fabrication offers significant cost savings—especially for medium to high-volume production. Modern fabrication technologies minimize material waste, accelerate production cycles, and reduce tooling costs. The ability to scale efficiently from prototypes to full-scale manufacturing makes sheet metal parts an economical choice for startups and established enterprises alike.

Precision and Consistency

Advanced fabrication methods—such as laser cutting, CNC punching, and automated forming—ensure that each sheet metal part meets tight tolerances and consistent quality standards. This precision is critical for applications where fit, function, and appearance are non-negotiable, such as aerospace, medical devices, and electronics.

How to Choose the Right Sheet Metal Parts Manufacturer

Selecting a reputable and experienced sheet metal parts manufacturer is crucial for project success. Key decision factors include manufacturing capabilities, material options, quality certifications, lead times, and customer support. Here are some actionable steps and important questions to consider during your selection process:

- Assess Technical Capabilities: Does the manufacturer offer the full range of fabrication services you need—such as laser cutting, CNC bending, welding, powder coating, and assembly? Can they handle your required materials and part complexities?

- Review Quality Standards: Look for manufacturers with ISO 9001 or other relevant certifications, robust quality control processes, and a track record of delivering precision parts on time.

- Evaluate Experience and Industry Expertise: Has the company completed projects in your specific sector, such as automotive, aerospace, medical, or electronics? Industry experience can ensure that your unique requirements are understood and met.

- Compare Lead Times and Scalability: Does the manufacturer have the capacity to meet your deadlines and scale from prototypes to full production efficiently?

- Request Samples and References: Ask for examples of previous work, case studies, and customer testimonials to verify quality and reliability.

- Obtain Detailed Quotes: Request transparent, itemized quotes from multiple suppliers to compare costs, turnaround times, and value-added services.

To ensure the best results when sourcing custom sheet metal parts, compare at least 4 to 5 manufacturers using our comprehensive list of sheet metal parts manufacturers. Each company profile highlights specific areas of expertise—such as prototype development, mass production, or advanced finishing capabilities—and provides direct contact links for quote requests and technical consultations.

Frequently Asked Questions About Sheet Metal Parts

What materials are commonly used in sheet metal fabrication?

Popular materials include stainless steel, carbon steel, galvanized steel, aluminum, brass, copper, and titanium. Each offers unique properties—such as corrosion resistance, conductivity, or weight savings—making them suitable for specific applications and environments.

How do I determine the right thickness for my sheet metal part?

The required thickness depends on factors such as load-bearing requirements, environmental exposure, desired weight, and regulatory standards. Consulting with a qualified sheet metal fabricator ensures optimal material selection and part performance.

What finishing options are available for sheet metal parts?

Common finishes include powder coating, anodizing, plating, painting, and polishing. These treatments improve corrosion resistance, appearance, and durability, and can be customized to your project’s needs.

Can sheet metal parts be customized for unique or complex applications?

Yes, advanced fabrication technologies—such as laser cutting, robotic welding, and CNC forming—enable the production of highly customized and intricate parts. Whether you need a single prototype or a high-volume production run, custom sheet metal fabrication can accommodate your requirements.

What industries benefit most from sheet metal parts?

Automotive, aerospace, construction, electronics, medical device manufacturing, telecommunications, food processing, and industrial automation are among the top sectors leveraging sheet metal parts for performance, safety, and innovation.

Ready to Start Your Sheet Metal Project?

Whether you’re designing a new product, upgrading equipment, or seeking a reliable manufacturing partner, high-quality sheet metal parts are essential to your success. Request a custom quote today or contact our team to discuss your unique specifications. Need help selecting the right material or manufacturing process? Explore our resources and connect with an expert for tailored guidance.

Related Resources and Search Prompts

Still have questions about sheet metal parts, custom metal fabrication, or metal manufacturing services? Contact us.

Broaching

Broaching CNC Machining

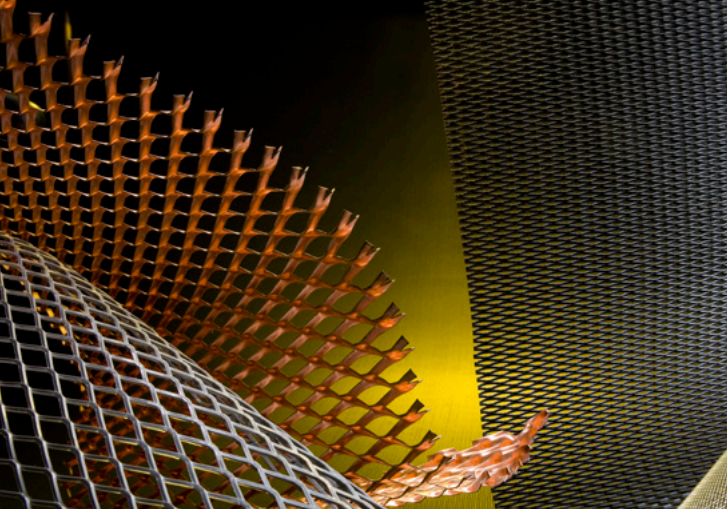

CNC Machining Expanded Metals

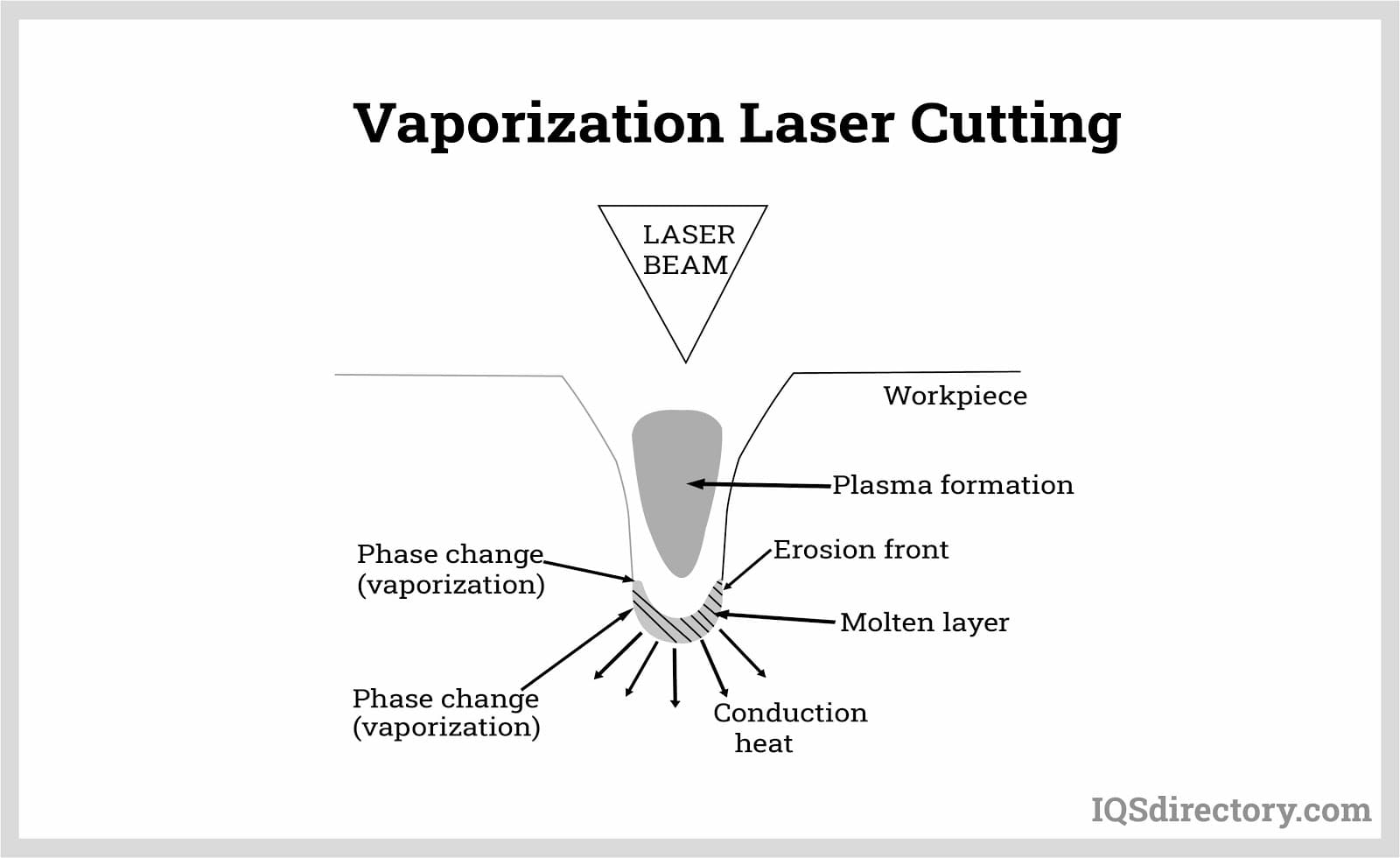

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

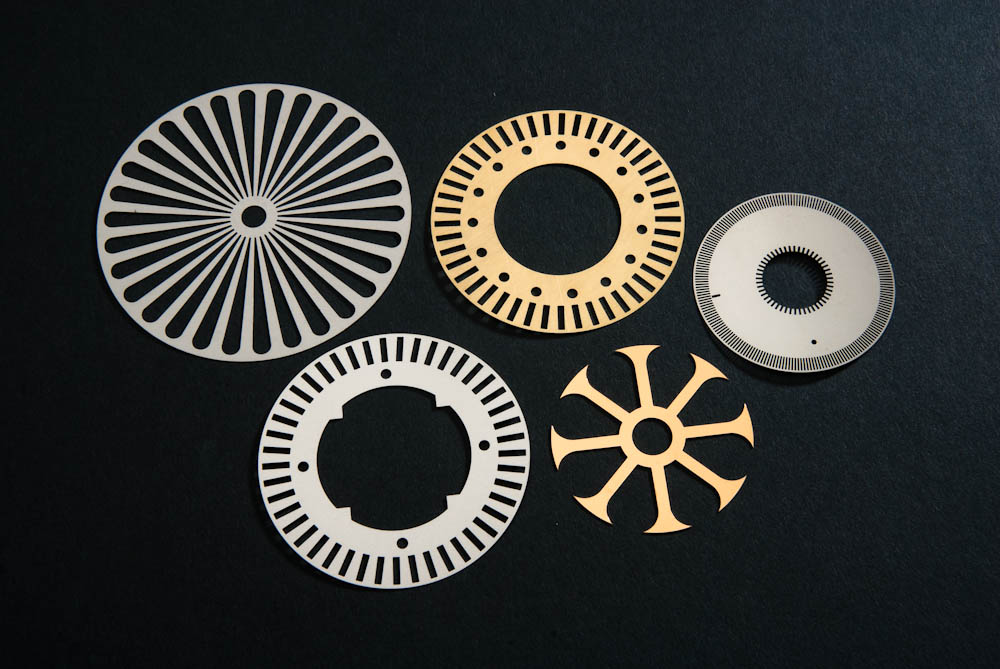

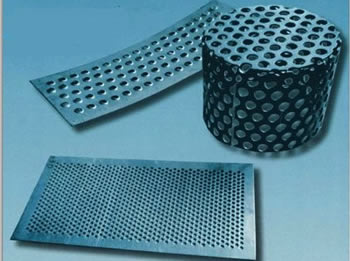

Metal Fabrication Perforated Metals

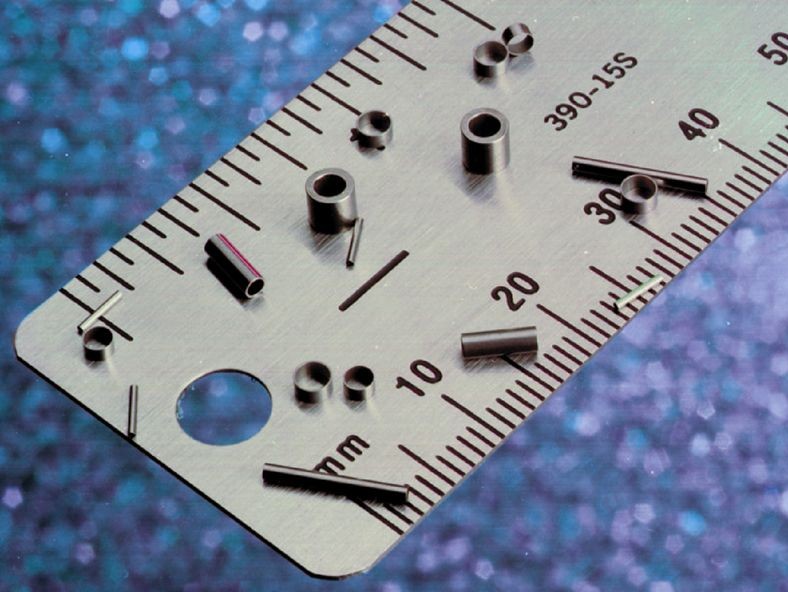

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

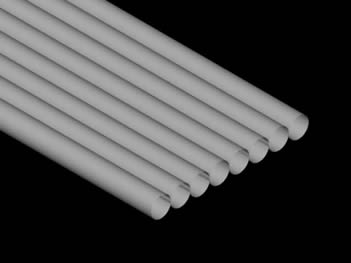

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services