The sheet metal forming industry in the United States alone produces millions of tons of metal annually. As the industry continues to expand and advance, so do the capabilities and services provided by these trained professionals who perform the sheet metal work. While the initial production of the thin plates of metal known as sheets involves the heating and rolling of raw materials such as aluminum, steel or stainless steel; the creation of finished metal products is often much more complicated. Once sheets are produced and quality inspected, the men and women of the industry provide numerous secondary and finishing operations such as bending, welding, annealing, cold rolling, drawing, extruding, spinning and forging as needed.

The variety of fabrication processes is not only convenient, but essential. Sheet metal suppliers produce an impressive range of unique and everyday items. From automotive and airplane paneling to bridges and architectural panels and even kitchen utensils or ornamental objects, sheet metal products are ubiquitous. Service centers provide various components to food processing, automotive, aerospace, construction, architecture, heating and cooling, telecommunications, medical and defense industries to name a few. Precision sheet metal design is crucial to many of these applications, though especially in construction, aerospace and other high stress applications where product failure can be costly and devastating./p>

Broaching

Broaching CNC Machining

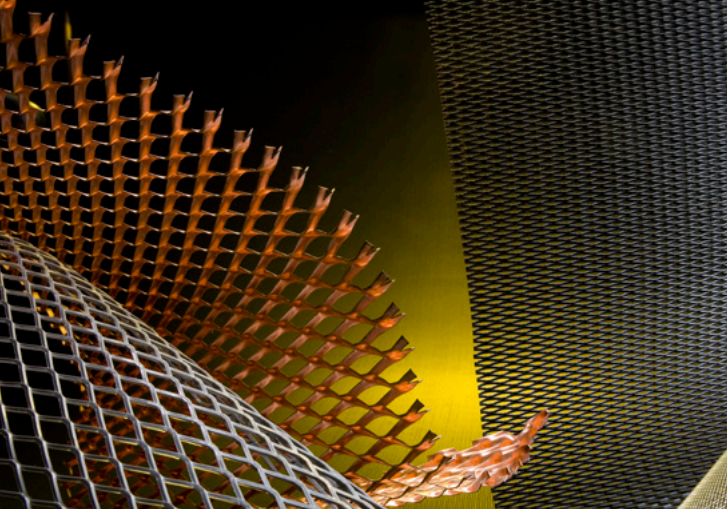

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

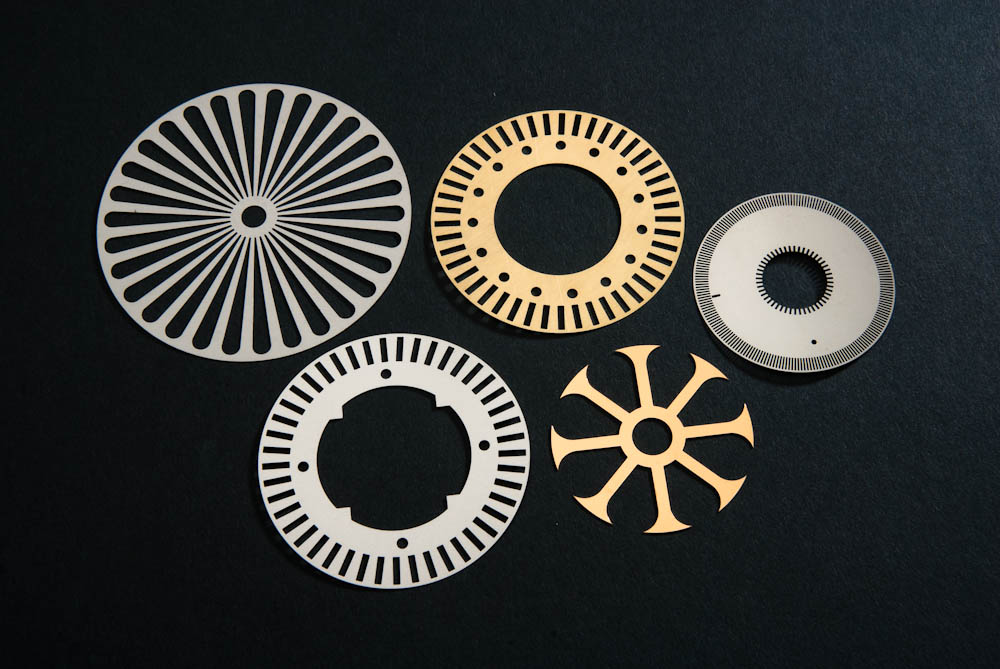

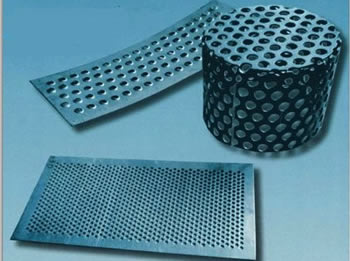

Metal Fabrication Perforated Metals

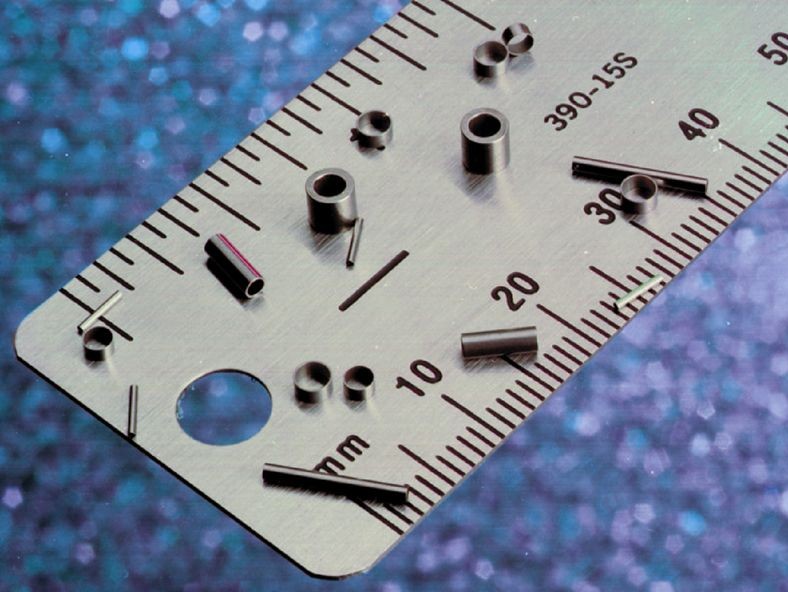

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

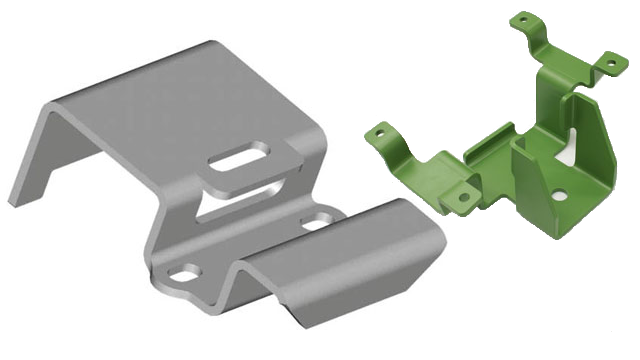

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services